Researchers are developing an eco-friendly alternative to petroleum for fine-chemical production. Their method uses solar energy to convert carbon dioxide (CO2) to methanol, which is then used to produce fine chemicals from plant dry matter.

Lignocellulosic biorefineries use plant biomass (lignin, cellulose and hemicellulose) rather than petroleum to produce energy, chemicals and other products. This process generates secondary by-products such as lignin or furfural that can be used to produce valuable fine chemicals like adhesives or perfumes.

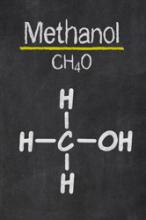

A key intermediate for converting plant biomass into fine chemicals is methanol, which reacts with, for example, furfural to produce fragrances and flavouring agents. The EU-funded 'Eco-friendly biorefinery fine chemicals from CO2 photo-catalytic reduction' (ECO2CO2) project aims to produce methanol from CO2 for use in biorefineries.

ECO2CO2 is developing a reactor that uses sunlight energy and water to transform CO2 to methanol via a photo-electro-chemical (PEC) reaction. Researchers aim to use a cost-effective method that does not require expensive catalysts and that has a conversion efficiency above 6 %.

Reducing greenhouse gas emissions by converting CO2 to methanol makes this an eco-friendly approach. As well as being cost competitive, successful development of a PEC reactor is in line with industry goals for resource- and energy-efficient chemical synthesi